- Empty cart.

- Continue Shopping

What is a Reorder Point ROP: Great Guide with Definition, Formula and Examples

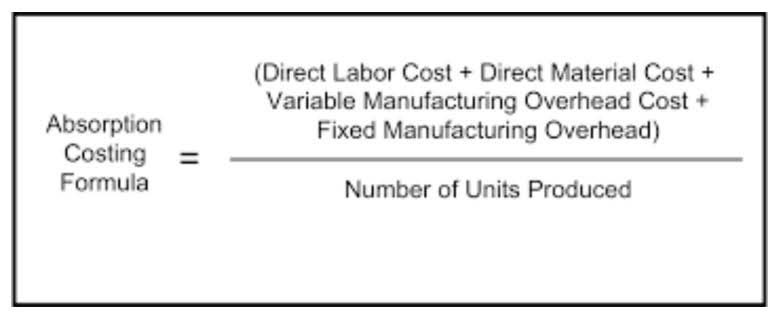

Bulk products that sit in a warehouse longer than planned can cause expenses to add up. It can impact factors like operational cost, tax, insurance, and deterioration of inventory. The importance of maintaining your stock reorder point increases during a peak season when the demand and website traffic is higher. Delay in the deliveries and not matching the ETA because of limited stock can impact your relationship with the customers and increase the chances of losing future business transactions. By using the reorder point formula, you know that when your inventory reaches 175 red bandanas, you need to replenish your inventory so you don’t experience shortages.

How to manage the Reorder Point in manufacturing companies?

Outdated inventory management systems may lack the capabilities needed for accurate ROP calculations. This makes the task of selecting a reliable supplier crucial for minimizing missing items, packing errors, and product quality issues—which harm your business’s reputation. That said, successful dropshippers carefully oversee the fulfillment process and are committed to providing a satisfying customer experience.

Reorder Point (ROP): Meaning, ROP Formula, and Calculations

Ordering at the right time ensures you always have items to sell, avoiding delays in fulfilling customer orders. Handling these calculations manually is doable, but as your inventory grows, it can become quite a task. You might want to think about using tools like Excel or dedicated inventory management software to help you keep track of your numbers more easily and efficiently. An effective reorder point ensures that your business keeps flowing— it helps you fulfill orders quickly, protects your margins, and keeps customers happy. By reordering a predetermined amount of replenishment inventory according to demand forecasts, you can avoid sunk costs from inventory shrinkage and obsolescence. To accurately calculate a product’s reorder point, it’s important to understand these factors and how they might impact your sales velocity.

What is a Reorder Point (ROP) – Definition and Formula

By looking at both the highest and average scenarios, you’re better prepared for surprises. Using correct and up-to-date lead time info is key for getting your reorder point just right. Ever what is rop in business bought something online and had to wait a while for it to show up at your door? A smart ROP plan works great with a good inventory system that can ping you when it’s time to reorder.

What is a good reorder point?

Conversely, it can be costly to replenish inventory when you completely run out. If you have to expedite getting product from your manufacturer, you’ll likely incur additional fees. Setting the Reorder Point (ROP) at the appropriate level offers several significant advantages for businesses. Knowing your ROP helps you place an order with enough time to receive, process, and restock it. Customers come around, they’re checking the shelves, they’re looking for a certain product, but you don’t have it because you didn’t order enough or didn’t receive them on time. In other words, if you want to run an efficient business, you can’t rely on intuition to determine when to reorder stock.

Ultimate WMS Requirements Guide: How to Choose the Best Ecommerce WMS

That will help ensure no interruption in production and save on extra costs. This system works by requiring managers to order more products when the current supply of products falls below a predetermined amount. Mattias is a content specialist with years of experience writing editorials, opinion pieces, and essays on a variety of topics. He is especially interested in environmental themes and his writing is often motivated by a passion to help entrepreneurs/manufacturers reduce waste and increase operational efficiencies.

Avoid stockouts

Shopify POS, for example, calculates ideal reorder points for products based on supplier lead times and the average number of sales per day. This ensures you know which products are running low on stock and have enough lead time to replenish inventory before quantities reach zero. Apart from the average time, you must calculate the lead time demand.

- It helps mitigate risks and ensures that the desired service level is maintained, even in unforeseen circumstances.

- It is, however, filled with a number of complicated terms, conditions, and options.

- The values used to calculate your reorder point and date are fully customizable for each SKU.

- This ambiguity arises from the challenges in accurately predicting market demand and supply chain inconsistencies.

- With a network of fulfillment centers around the United States and technology that’s integrated with the leading ecommerce platforms, ShipBob helps brands improve their shipping strategy.

Do you want to find the Reorder Point for your Parts?

By reordering before you’ve run out of inventory, you ensure you don’t have a gap in the products and services you can offer customers. If a customer orders three items from three different suppliers, you’ll need to cover separate shipping costs for each. Use dropshipping to offer a wide array of trending products to your customers. With no unsold inventory to worry about, you can change your product catalog at will.